- Oil-free Air Compressor

- Oil-free Air Blowers

- Scroll Air Compressor

- Air Compressor

- Stationary Air Compressor

- KAISHAN LG Series

- KAISHAN LG 2-stage

- KAISHAN LG Water-cooled

- Kaishan KSZJ diesel

- Boreas Screw Compressor

- Boreas BMVF Series

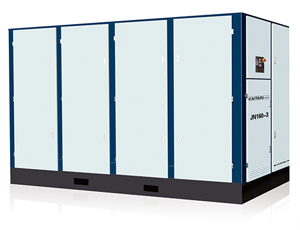

- KAITAIN JN Series

- KAITAIN JN 2-stager

- Kaitain JN Integrated

- Kaitain JN High Pressure

- Kaitain PMVF series

- Kaitain JN 0.3Mpa

- Kaitain JN 0.5Mpa

- Portable Air Compressor

- Kaishan KSCY diesel

- KAISHAN LGCY Diesel

- KAISHAN LGY Electrical

- KAISHAN LGCY 2 Stage compression Diesel

- KAISHAN KSDY Electrical

- KAISHAN ML Explosion-proof

- KAISHAN LGJY Mining

- KAISHAN LGN Series

- KAISHAN LGYT Mining

- Piston Air Compressor

- KAISHAN KA series

- KAISHAN KB Series

- KAISHAN KJ Series

- KAISHAN KS Series

- KAISHAN Mining Series

- Kaitec Screw Vacuum Pump

- High-speed Single-stage Centrifugal Blower

- Industrial Refrigeration Heat Pump Applied Screw Compressor

- Centrifugal Air Compressor

- Centrifugal Steam Compressor

- Centrifugal Refrigerating Compressor

- Gas Air Compressor

- ORC Screw Expansion Power Station

Centrifugal Air Compressor

Thanks to excellent packaged design, the air compressor is of compact structure, easy to install and convenient to maintain and inspect.

It adopts internationally excellent NREC software design and its core component, impeller, is processed by Hermle Five-Axis Machining Center.

Impeller and diffuser, which are independently designed according to actual working condition of the customer, have less energy consumption than that of the competitor’s product.

Compared with piston compressor and screw compressor, it saves more energy and has only a few parts to be maintained, thus its maintenance cost is low.

The element of double oil filter can be changed without stopping the filter.

Dry type diaphragm coupler is efficient and maintenance free without adding lubricating oil.

Drawer-type water pipe cooler is easy to clean and maintain on the site.

Each water pipe of the cooler is equipped with hand valve to regulate water volume of each cooler and guarantee cooling effect.

The gearbox is horizontally split, which simplifies inspection and maintenance of sealing element and bearing.

It adopts advanced PLC control system to monitor flow, pressure, temperature, and vibration value in real time so as to guarantee safe and stable operation of the unit. It is also easy to operate by users.

Bearing temperature and shaft vibration monitoring.

The air intake filter is designed with twice flow to reduce pressure loss and energy consumption and extend maintenance period.

Reliable sealing system design provides you with 100% oil-free compressed air.

Inlet guide blade regulator save more power than the inlet valve.

It runs reliably, stably and efficiently with small vibration and low noise.

It has self-sustained pressure lubrication system and main and auxiliary oil pump to guarantee lubrication of the gearbox.

It has rough grade spiral wheel to guarantee smooth operation of the gear.

Tilting-pad bearing is used to improve stable operation of the rotor.

The thrust ring is used to reduce mechanical loss.

Compressed air heat recovery scheme is customized according to customer requirements to provide hot water at 60~90 °C for shower or process flow.

Technical Parameters of Centrifugal Air Compressor

Model |

Capacity Nm3/min |

Working pressureMPa |

Rated motor powerkW |

Size mm |

KCC100~KCC160 |

100~160 |

0.3~1.0 |

400~900 |

4500x2000x3000 |

KCC160~KCC250 |

160~250 |

0.3~1.0 |

600~1400 |

5000x2200x3000 |

KCC250~KCC400 |

250~400 |

0.3~1.0 |

1000~2200 |

5500x2600x3000 |

KCC400~KCC600 |

400~600 |

0.3~1.0 |

1600~3400 |

8000x5000x4000 |

- Drill Rigs and Rock Drills

- TopHammer Drilling Rigs

- KL511 top hammer drilling rig

- KL510 top hammer drilling rig

- Tunneling jumbos(1 boom)

- KJ211 Tunneling jumbo

- KJ212 Tunneling jumbo

- KJ310 Tunneling jumbo

- KJ311 Tunneling jumbo

- KJ311 higher Tunneling jumbo

- KJ311 double Tunneling jumbo

- KJ311plateau Tunneling jumbo

- KJ311 Diesel Tunneling jumbo

- Face drill rigs(2 boom)

- KJ421 Tunneling jumbo

- KJ422 Tunneling jumbo

- Rock Bolting Rigs

- KM211 Rock Bolting Rig

- KM311 Rock Bolting Rig

- Tunneling DTH Rigs

- KS311 DTH Rig

- KSQ31 DTH Rig

- Tunneling Scaling Rigs

- KQ311 Scaling Rig

- Top Drive Drilling Rig

- KMD150 Anchoring Drill Rig

- Integrated DTH drilling rigs

- KT5C/YT5C DTH drilling rig

- KT6C DTH drilling rig

- KT7C DTH drilling rig

- KT9C DTH drilling rig

- ZT5 DTH drilling rig

- ZT10 DTH drilling rig

- KT11 DTH drilling rig

- KT12 DTH drilling rig

- KT15 DTH drilling rig

- KT20 DTH drilling rig

- KT25 DTH drilling rig

- KT30 DTH drilling rig

- KT20S DTH drilling rig

- RK60 DTH drilling rig

- Crawler DTH drilling rigs

- KG310 DTH drilling rig

- KG320 DTH drilling rig

- KG410 DTH drilling rig

- KG420 DTH drilling rig

- KG420S DTH drilling rig

- KG430 DTH drilling rig

- KG430S DTH drilling rig

- KG510 DTH drilling rig

- KG520 DTH drilling rig

- KG590 DTH drilling rig

- KG610 DTH drilling rig

- KG9 DTH drilling rig

- KG920BHIII DTH drilling rig

- KG726HIII DTH drilling rig

- KGH3AIII DTH drilling rig

- DTH Drilling rig

- Rock Drills and Jack Hammer

- Hand-held Rock Drill

- Air-leg Rock Drill

- Pneumatic Rock Drill

- Water Well Drilling Rig

- Crawler Water Well Drilling Rig

- Wagon Water Well Drilling rigs

- Core Drilling rigs

- Road Machinery

- Air Pick

- Auxiliary Equipment